The power of the sea is a force

to be reckoned with

A wind farm offshore work vessel requires critical attributes in terms of speed, seaworthiness, environmental efficiency, crew comfort, the need for a stable work site platform and sea mammal protection to avoid expensive delays during migrations. It is a little known fact that 90% of the population get seasick, with some becoming incapacitated for hours or even days. This equates to crew safety, loss of productivity and manpower at the offshore work site.

It is all about “getting there and being there”

What's wrong with the offshore wind farm CTVs used today

Currently popular, conventional “high speed” ferry catamarans and recreational power catamarans originally designed for inshore use are being converted to offshore work boats but they fail to address critical issues of offshore work. Efforts have been attempted to use hydrofoil technology to overcome the speed and motion shortcomings of catamarans for offshore work vessels without success. SWATH (small waterplane twin hull) vessels using 70 year old technology offer some offshore stability at the price of very low speeds, high energy demands and sea mammal collisions. Surface effect craft (WIGs) using aircraft technology offer speed, comfort and efficiency, but they are dangerous and have no practical work boat ability at slow speeds.

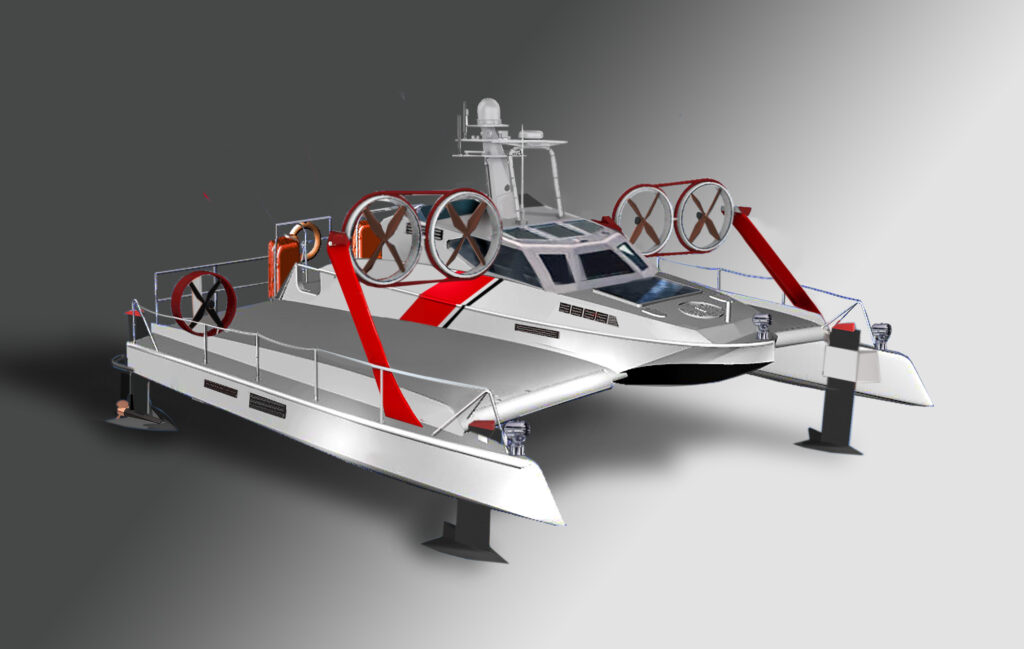

Amphfoil CTV: the breakthrough hybrid electric CTV and support boat solution

Amphfoils obtained international patent coverage to create the first-time-in-history “green” surface

skimming boat that addresses all these important issues.

Amphfoil CTV vs. conventional catamarans

The catamaran is a watercraft featuring two parallel hulls of equal size with a platform or deck structure connecting the hulls. The underwater design of the hulls typically use a design fashioned in the 1950’s for aluminum and polyester fiberglass construction. The basic design of these narrow dual hulls demands incredibly large, inefficient marine engines mostly (water pump “jet” propulsion) in order to reach “high” (25-30 knots) top speeds resulting in very high fuel consumption and a terrible carbon footprint. The inefficient hull shapes with large engines that pollute the air and water are the antitheses of green energy. Also, a major negative side effect of water pump propulsion is massive wake turbulence affecting shoreline areas and sensitive ecosystems.

Compounding the environmental issues, conventional catamarans have a notorious reputation for body punishing motion and motion sickness issues in inshore applications called “the vomit comet effect”. The total lack of forward buoyancy creates a pitching and pounding action that slows the boat and negatively affects everyone aboard. The high boxy deck house structures evolved from inshore ferries also creates energy stealing drag issues causing additional fuel burn and related pollution.

Hydrofoil Catamarans

Hydrofoil technology has been attempted since 1898 with little/no general acceptance. After many decades of expert R&D and countless millions of expenditure all of the major navies in the world including the United States have abandoned hydrofoil vessels. There are many problems with hydrofoil technology but the biggest are maintaining foil lift speeds and keeping the foils fully submerged when encountering the troughs between wave heights. It takes a tremendous amount of energy to obtain the necessary speeds to lift a catamaran or conventional hull up on to the relatively small hydrofoils. The speed must be maintained at all times to maintain lift on the fully submerged hydrofoils regardless of sea state conditions. Added to the problems of hydrofoils is the massively complex and expensive water propeller drives that must be incorporated into the hydrofoil apparatus for propulsion. In today’s world where energy demand has a direct correlation to major climate change issues hydrofoil catamarans only offer speed in calm water have no real advantage.

Amphfoil CTV: the "catamaran" made energy-efficient

and seaworthy

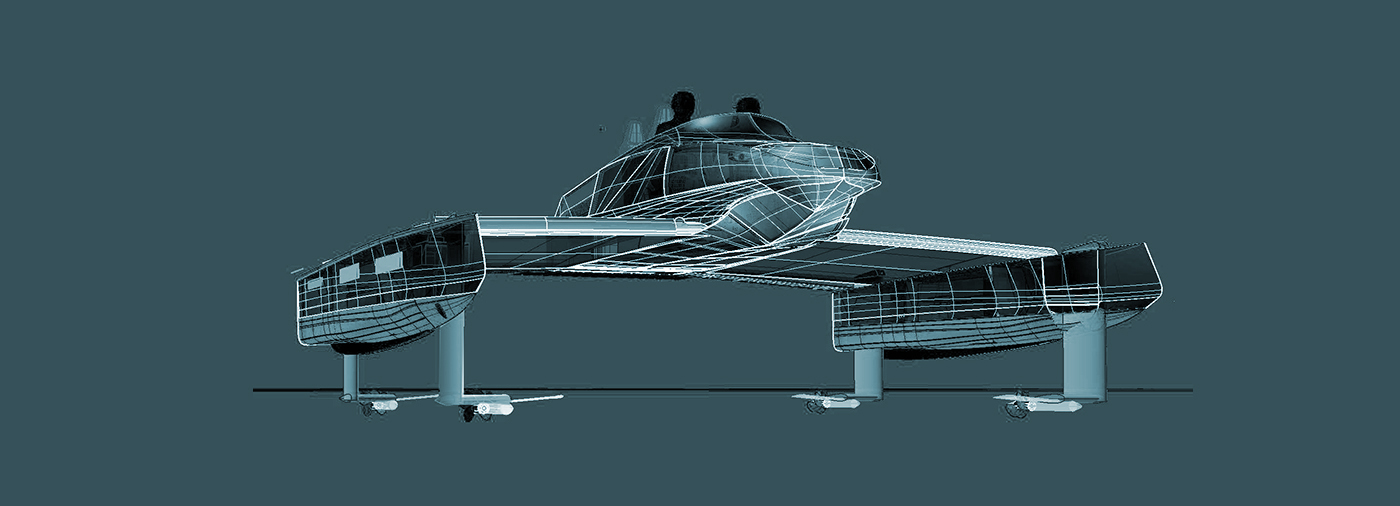

In a very broad interpretation of the term, Amphfoils are twin-hulled catamarans at speeds under 10 knots. However, several important factors separate Amphfoils from other catamarans. The hulls on an Amphfoil use proven and patented high lift, low energy/thrust, aerodynamic design that cuts power requirements by 66%. Amphfoils incorporate wave piercing, retractable Seafoils to reduce surface in contact with water further reducing energy demand.

Amphfoil’s advantages are a critical factor for electric propulsion due to low battery/energy demand and increased range. Light weight 21st century epoxy molded materials like Kevlar and carbon fiber insure strength, durability, low maintenance and reduced power demands.

Amphfoils also use sustainable aerodynamic and hydrodynamic lift to reduce hull immersion and drag. The aerodynamic-configured deck structure designs placed aft reduces drag and dampens motion. To further increase efficiency and comfortable motion at any speed, Amphfoils incorporate quiet, electric air propellers that provide both lift and propulsion. It is a documented fact that air propellers are 34% to 42% more efficient than water propellers. The combination of Amphfoil hull design, aerodynamic surface effect lift, low drag Seafoils and air propellers create a work boat with unparalleled motion, speed and efficiency compared to any catamaran ever built to date.

Amphfoil CTV: Better than SWATH vessels

Amphfoils use wave piercing technology in the Seafoils. Wave piercing as a concept has been around for over 70 years to deal with the serious problems of pitching and pounding motion found in conventional catamaran designs. In recent years some designers and builders have embraced “wave piercing” technology in relatively large catamarans called SWATH (Small Waterplane Area Twin Hull). While SWATH basically addresses these issues, the solution comes at a very high price in terms of slow speed, complex construction, high power demands and marine mammal fatalities.

Basically SWATH catamarans have two completely submerged hulls large enough to support the full weight and required buoyancy of the center structure. Pulling these hydrodynamically-shaped submerged hulls through the 850 times dense, or “molecular mud “ called water, takes a tremendous amount of energy. These deep, fully submerged hulls are always in place regardless of the sea state. It is a documented fact that even in areas that have notorious sea and wave conditions, the seas are relatively calm 35%-50% of the time. This variable sea state condition translates into wasted and unnecessary energy expenditure when conditions do not require wave piercing stability. Also, SWATH designs do not fully address rolling motion in offshore ocean wave conditions.

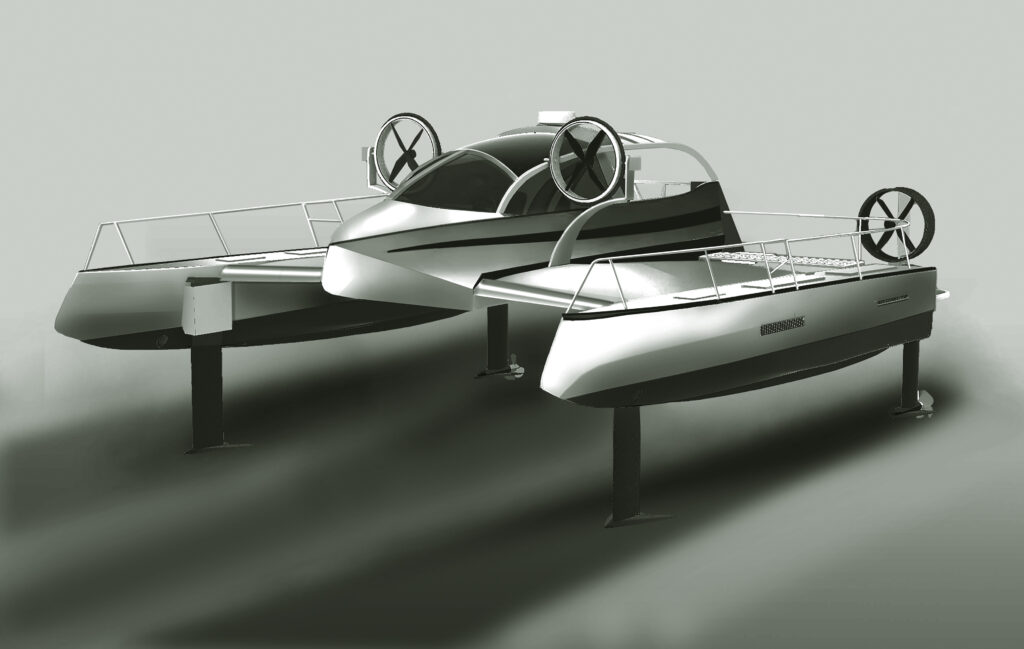

Amphfoil CTV: stabilized with speed and efficiency

Unlike SWATH technology, Amphfoils were designed from day one with a focus on reducing energy demand, reducing motion at high speed and the critical issue of offering a stationary work platform in offshore sea conditions that is safe and crew productive. Rolling motion in a seaway underway or at full stop is one of the biggest challenges facing the offshore wind industry. It is a well-documented fact that vessel length, depth and weight alone will not mitigate rolling motion in ocean swells evidenced by large cruise ships and military vessels that use various methods of “active” anti-roll stabilization systems. It is also a well-known fact that conventional catamaran twin hulls are difficult to stabilize due to the conflict of each hull encountering a different period of rolling motion at the exact same time.

Amphfoil’s Seafoils are especially designed to dampen rolling motion during stationary work operations. Using fully submerged and proven non-mechanical Paravane technology used extensively on offshore fishing vessels for decades, Amphfoil’s twin Seafoils avoid the conflict of twin hulls rolling at different periods/heights of wave created swells at any given time. The design shape of Seafoils has one Seafoil encountering resistance as it is being pushed down while the other Seafoil is encountering resistance as it is being lifted up. This paravane technique is the basis for Amphfoil’s antiroll characteristics.